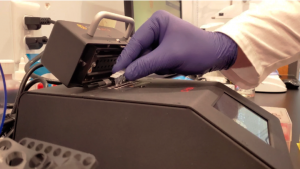

The Grimross Craft Beer Brewery had the tools to test for the virus among its own equipment.

Be it yeast or virus, both contain genetic material.

So, when a Fredericton craft brewery bought a genetic testing machine earlier this year to test their beers — it inadvertently also bought a machine capable of testing for COVID-19.

“I didn’t know this,” said Stephen Dixon, president and CEO of Grimross Craft Beer Brewery. “My lab tech, Devin, he told me “Oh, by the way, this machine is the same machine that tests for COVID-19 or viruses in general.’

“Turns out we can do it.”

A quantitative polymerase chain reaction machine, or qPCR machine, identifies what species a sample of DNA or RNA comes from — be it cells, bacteria, or viruses — as well as how much genetic material is present.

Grimross originally purchased it to detect any unwanted bacteria in the company’s beer that could throw off the flavour from batch to batch.

But with a quick update to its open-source software, it’s now able to identify if the virus is in a saliva sample from a Grimross employee.

“We’re going to endeavour to test all of our staff on a fairly regular basis, just for peace of mind and to make sure we’re not exposing anybody to the virus and keeping everybody safe,” said Dixon.

Dixon isn’t mandating that any of his staff get tested at the brewery if they’re not comfortable. All they need to do is spit into a test tube.

“This is actually a less intrusive test,” said Dixon. “Some of the tests people may have heard about, you have to go through the nasal cavity. You have to go up quite far. This one is actually done with saliva.”

Results come out 24 hours later, and so far everyone has tested negative, including Dixon.

Just a test

But brewery staff are the first to admit they’re not doctors.

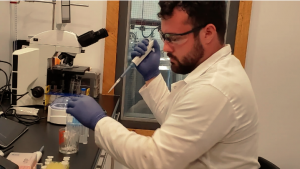

“Even if we get a positive result, which we haven’t, we’re not a medical lab,” said Devin Kearney, the brewery’s quality control technician.

If an employee has any positive results or even just symptoms, they would be immediately sent to be tested by medical experts.

“It’s basically a ‘you’ve got it’ or ‘you could have it, then you should go get tested by the province, who can then give you an official statement,'” said Kearney, who has a bachelor’s degree in biology.

“If we were to discover somebody was positive, the first thing we’d do is have them contact the province to have them get tested with their systems,” said Dixon. “We’re not considering ourselves to be official. We’re not certified, we’re not sanctioned in anyway, so we’re not telling people they’ve got certified or sanctioned results even though we know the machine works.”

It was Kearney who first realized the brewery had the tools to test for the virus. A recent science graduate, he was originally hired at Grimross to work in packaging.

“I got hired to put cans in boxes and then put them on top of other boxes with cans in them,” said Kearney.

But after going deeper into his resumé, Dixon hired him to work in an expanding quality-control role, and soon after Kearney realized the fledgling lab he was working in had capabilities outside of testing beers.

He then presented the idea of testing for COVID-19 to Dixon, and they put an order in for the raw materials needed to complete the tests. After a long wait, the order arrived last week and so far he has tested about half of the two dozen or so Grimross employees.

“We did our first round of tests on everybody that works in the back of the house in production, and this week we’re going to be testing everybody that works in the taproom,” said Kearney.

Kearney said the brewery’s qPCR machine can also detect antibodies for COVID-19 in genetic samples, so Grimross can also tell if any staff had the virus at one point and recovered. So far, all those tests have shown negative results as well.

Dixon said he told the province Grimross had the capability to test for COVID-19 in the early days of the virus’s presence in the province. He said he offered to help with testing if extra resources were needed but never heard back.

So, for now he’s content with just protecting his staff and ensuring the beer is as safe as possible. And he’s not ruling out some marketing to go along with that.

“I suppose it doesn’t hurt to let people know that we are taking very good care of the beer that we make,” said Dixon.

Find Shane Fowler’s full CBC story HERE